| Place of Origin: | CHINA |

| Brand Name: | LiangRu |

| Certification: | ISO9001 |

| Model Number: | RL-10 |

| Minimum Order Quantity: | Different goods has different MOQ |

|---|---|

| Price: | negotiable |

| Packaging Details: | plywood cases or as you required |

| Delivery Time: | 15-25days |

| Payment Terms: | T/T,L/C or others |

| Supply Ability: | sufficient supply |

| Function: | Printing | MOQ: | According To Order |

|---|---|---|---|

| Quality: | GOOD Quality | Packaged: | Standard Export Package |

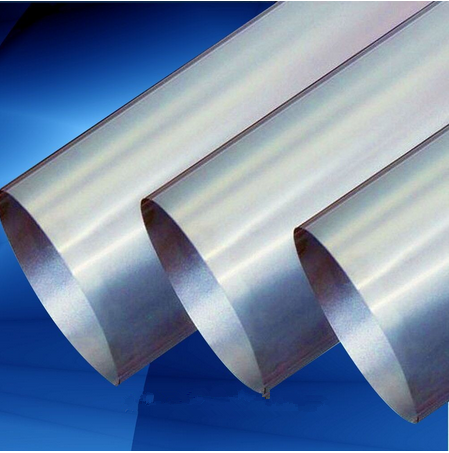

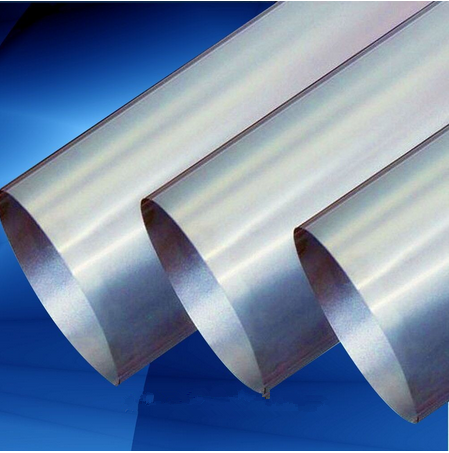

| NAME: | Rotary Screen | Color: | As Product |

Rotary Screen Clinder Textile Machinery Spare Parts High Temperature Resistance

As previously noted, the flooding and printing action on a rotary system is all part of the same continuous motion, and separate strokes for these functions are not required. The situation is a little different with flatbed presses. On a flatbed press, printing is a two-step process that involves a pass over the screen by the floodbar to fill mesh openings with ink, followed by a squeegee pass to bring the stencil and substrate into contact for ink transfer. Not only does this approach reduce printing times, but it also removes the floodbar as a variable from the printing process.

Rotary vs. flat screen printing

What is rotary screen printing?

(The impression roller serves the same function as the press bed on a flatbed press.) As the web passes through the rotary unit, the screen spins at a rate that identically matches the speed of substrate movement.Rotary screen printing is so named because it uses a cylindrical screen that rotates in a fixed position rather than a flat screen that is raised and lowered over the same print location. Rotary presses place the squeegee within the screen. These machines are designed for roll-to-roll (web) printing on flexible materials ranging from narrow web films to wide-format roll textiles.In rotary printing, the web travels at a consistent speed between the screen and a steel or rubber impression roller immediately below the screen.

Delivery time: within 15 to 25 days

Package:plywood cases or as you required

Buyers show:

Black Roll Cotton Stenter Brushes Wheel Mini For Textile Machinery

Custom Textile Machinery Spare Parts Color Paste Pump For Rotary Screen Printing

Stainless Steel Expanding Roller Opener Cylinder Hydraulic High Stability

Textile Machinery Flat Selvedge Uncurler Electrical For Stenter Nylon

High Strength Guided Vertical Clip Chain Smooth For Stenter Machine Patrs

Manganese Stenter Machine Parts Anti - Rust Germany Krantz Pin Holder

High Density Rotary Printing Machine Spares , 20mm Rotary Magnetic Rod

Elastic Rotary Printing Machine Spares Dimensional Stability Aluminum 640 End Rings

640 Die Cast Rotary Printing Machine Spares Zimmer Type End Ring