| Place of Origin: | CHINA |

| Brand Name: | LiangRu |

| Certification: | ISO |

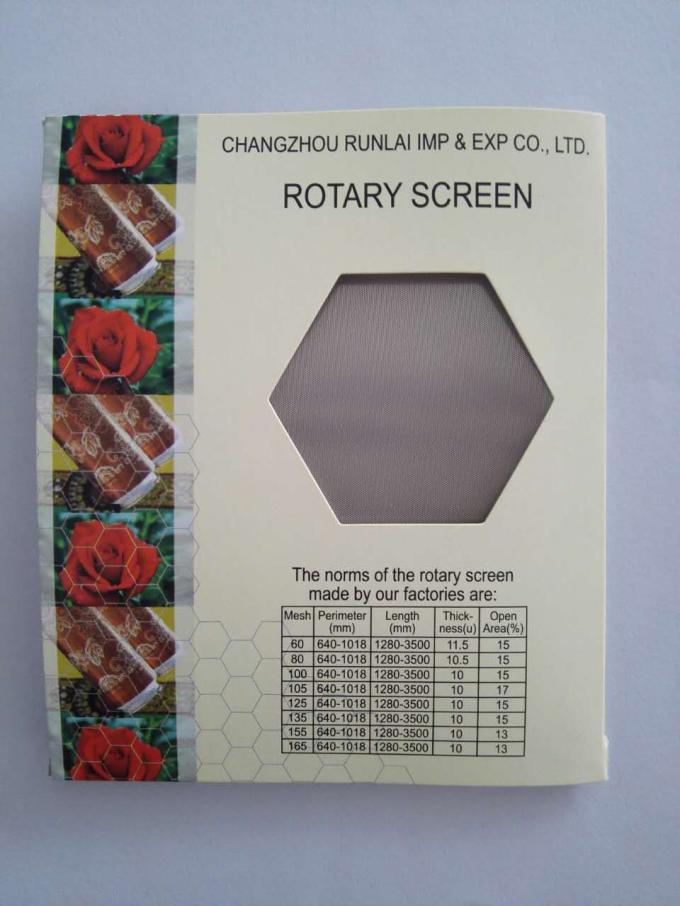

| Model Number: | 155M |

| Minimum Order Quantity: | Different goods has different MOQ |

|---|---|

| Price: | negotiable |

| Packaging Details: | plywood cases or as you required |

| Delivery Time: | 15-25days |

| Payment Terms: | T/T,L/C or others |

| Supply Ability: | sufficient supply |

| Product Keywords: | Rotary Screen Printing | Condition: | New |

|---|---|---|---|

| Material: | NICKEL | Type: | Rotary Screen |

| Supply Abilit: | According To Customer Demand For Supply | Quality: | Comparable |

155M Good Symmetrical Use High Mesh Rotary Nickel Screen Printing

Applications:

Our raw material of nickel is high purity and with less sulfur. Match it with high quality pure additives. Our products has unparalleled excellence performance. Printing ink penetration uniform, Photo emulsion and Sensitizer adhesion is strong bonding, high toughness, high elasticity, good thickness and uniform open area.This product is for new type rotary printing machine. After install endring on two ends and engraved designs on it, we can put the rotary screen on machine. Suitable for print cotton, silk, polyester, wall paper and etc.

What is rotary screen printing?

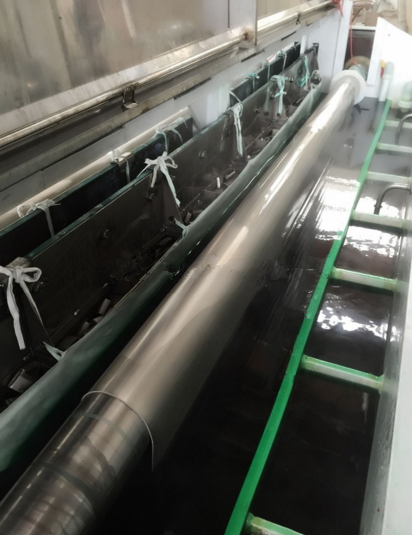

Rotary screen printing is so named because it uses a cylindrical screen that rotates in a fixed position rather than a flat screen that is raised and lowered over the same print location. Rotary presses place the squeegee within the screen. These machines are designed for roll-to-roll (web) printing on flexible materials ranging from narrow web films to wide-format roll textiles.

In short, rotary printing is a continuous, stepless image-transfer method. The geometry of the screen and the position of the squeegee within the screen combine to provide both the screen-flooding and image-transfer functions in a single smooth operation that repeats with every revolution of the screen.

The squeegee on a rotary press is in a fixed position with its edge making contact with the inside surface of the screen precisely at the point where the screen, substrate, and impression roller come together (Figure 1). Ink is automatically fed into the center of the screen and collects in a wedge-shaped "well" formed by the leading side of the squeegee and the screen's interior surface. The motion of the screen causes this bead of ink to roll, which forces ink into stencil openings, essentially flooding the screen without requiring a floodbar. The squeegee then shears the ink as the stencil and substrate come into contact, allowing the ink to transfer cleanly to the material.

In rotary printing, the web travels at a consistent speed between the screen and a steel or rubber impression roller immediately below the screen. (The impression roller serves the same function as the press bed on a flatbed press.) As the web passes through the rotary unit, the screen spins at a rate that identically matches the speed of substrate movement.

Description:

Our products has unparalleled excellence performance. Printing ink penetration uniform, Photo emulsion and Sensitizer adhesion is strong bonding, high toughness, high elasticity, good thickness and uniform open area.Our raw material of nickel is high purity and with less sulfur. Match it with high quality pure additives.

Our raw material of nickel is high purity and with less sulfur. Match it with high quality pure additives. Our products has unparalleled excellence performance. Printing ink penetration uniform, Photo emulsion and Sensitizer adhesion is strong bonding, high toughness, high elasticity, good thickness and uniform open area.

Your smart purchase for fantastic pattern

High mesh nickel screens bring a different pace and intensity to the printing industry,which set a whole new benchmark for fine print technology.

Specifications:

high open area,

good toughness & elasticity,

can be used for 5~7 times repeatedly,

saving dyestuff,

bear high temperature

The screens are made from the high quanlity Ni metals. The pattern frame of the screen is orderliness and the character is more tough and tensile. So the quality of nickel screen is slap-up. The pattern of the screen is printed symmertrical. Because of the more tough and tensile character, the screen will be used longer. So the screen is enable to be operacter, the during long-term and used to print patterns.

Competitive Advantage:

rotary printing screen export

More tough and tensile

High open area

identical repeats

longer printing lengths

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

FAQ:rotary srcreen

Q1:Why choose us?

We are dedicated to provide all kinds of spare parts for dyeing and finishing machinery. Top quality with

competitive price and sincere service is our key weapon to make more and more clients to choose and stay

with us. Choose us, choose unique!

Q2:Who needs your rotary screen printing?

A: Any companies who need spare parts use for standard rotary screen for dot coatings to interlinings.

Q3:Which kind of product dose your rotary screen?

A: We can provide for every Mesh.Like:40 Mesh to 165 Mesh

Q4:Is there a special specifications for your company?

A:For other specifications can be customized seperately(example:14mesh,17mesh,20mesh,25mesh.

30mesh).

We can offer free samples:

Black Roll Cotton Stenter Brushes Wheel Mini For Textile Machinery

Custom Textile Machinery Spare Parts Color Paste Pump For Rotary Screen Printing

Stainless Steel Expanding Roller Opener Cylinder Hydraulic High Stability

Textile Machinery Flat Selvedge Uncurler Electrical For Stenter Nylon

High Strength Guided Vertical Clip Chain Smooth For Stenter Machine Patrs

Manganese Stenter Machine Parts Anti - Rust Germany Krantz Pin Holder

High Density Rotary Printing Machine Spares , 20mm Rotary Magnetic Rod

Elastic Rotary Printing Machine Spares Dimensional Stability Aluminum 640 End Rings

640 Die Cast Rotary Printing Machine Spares Zimmer Type End Ring